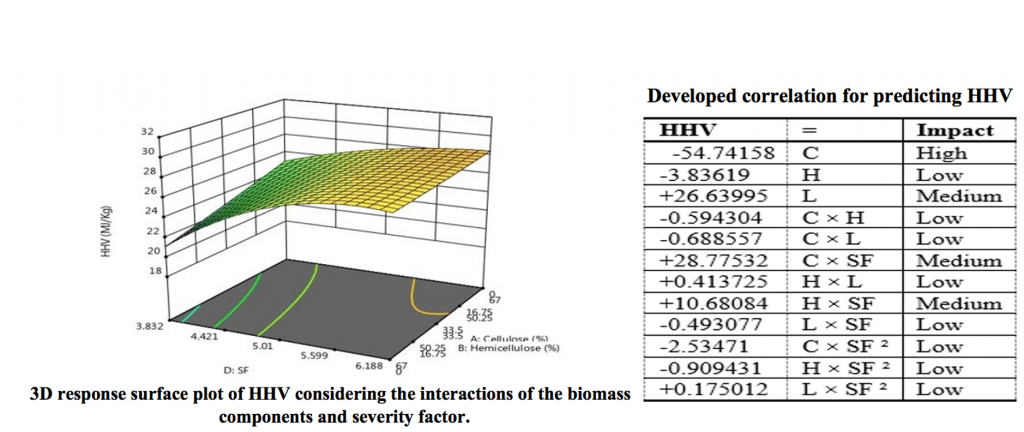

Prediction of hydrothermal carbonization with respect to the biomass components and severity factor

Reference: Heidari, M., Norouzi, O., Salaudeen, S., Acharya, B. and Dutta, A., 2019. Prediction of hydrothermal carbonization with respect to the biomass components and severity factor. Energy & Fuels, 33(10), pp.9916-9924.

Link: https://pubs.acs.org/doi/abs/10.1021/acs.energyfuels.9b02291

Summary: The goal of this study is to establish a link between the composition of biomass and the expected hydrochar from HTC. Using the experimental data, an attempt was made to generate model equations that can predict the mass yield, higher heating value (HHV), carbon content (C%), and energy recovery factor of the hydrochars according to the biomass composition and the process severity.

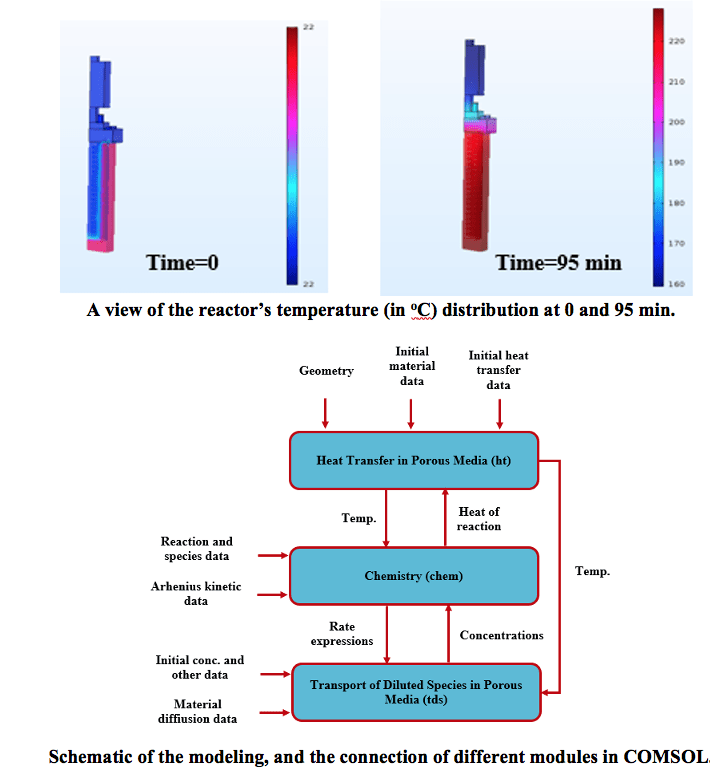

Development of a mathematical model for hydrothermal carbonization of biomass: Comparison of experimental measurements with model predictions

Reference: Heidari, M., Salaudeen, S., Arku, P., Acharya, B., Tasnim, S. and Dutta, A., 2021. Development of a mathematical model for hydrothermal carbonization of biomass: Comparison of experimental measurements with model predictions. Energy, 214, p.119020.

Link: https://www.sciencedirect.com/science/article/abs/pii/S0360544220321277

Summary: A mathematical model for hydrothermal carbonization (HTC) was developed by incorporating heat transfer rate, reaction kinetics, and the porous structure of the biomass using various modules of COMSOL Multiphysics software and was validated by experiments.

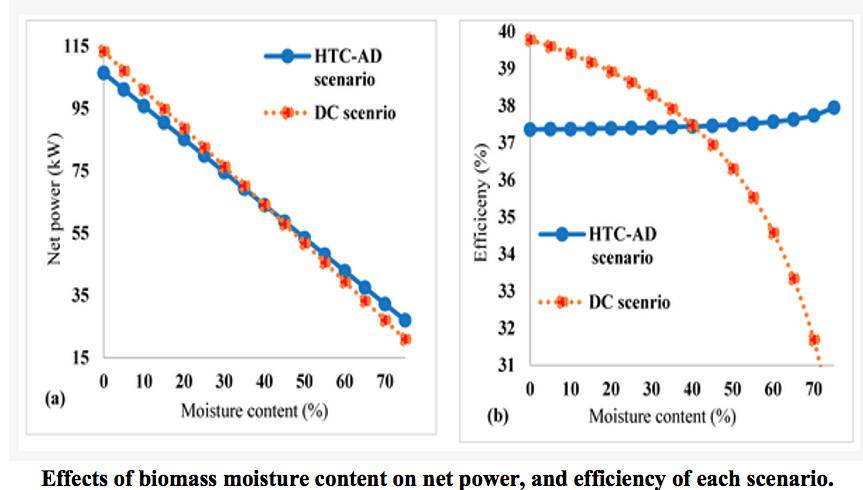

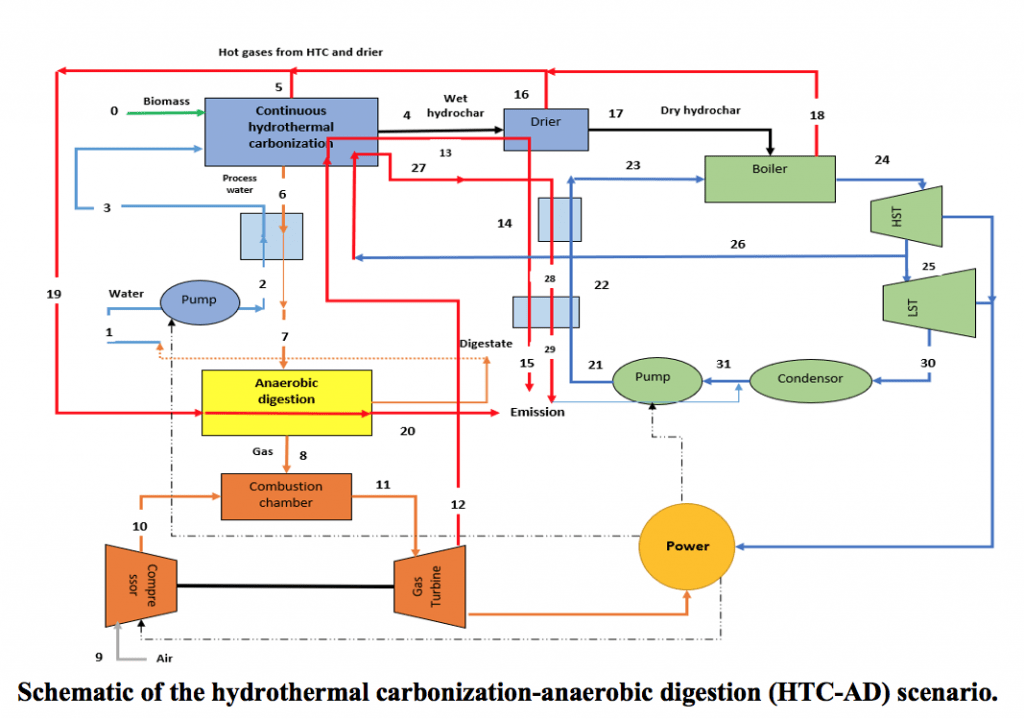

Numerical comparison of a combined hydrothermal carbonization and anaerobic digestion system with direct combustion of biomass for power production

Reference: Heidari, M., Salaudeen, S., Norouzi, O., Acharya, B. and Dutta, A., 2020. Numerical comparison of a combined hydrothermal carbonization and anaerobic digestion system with direct combustion of biomass for power production. Processes, 8(1), p.43.

Link: https://www.mdpi.com/2227-9717/8/1/43

Summary: Energy and mass balance equations of a combined HTC-AD system for electricity and heat generation was developed using Engineering Equation Solver (EES). The performances of the proposed systems were evaluated, and a sensitivity analysis was presented to help in finding the best operational conditions.

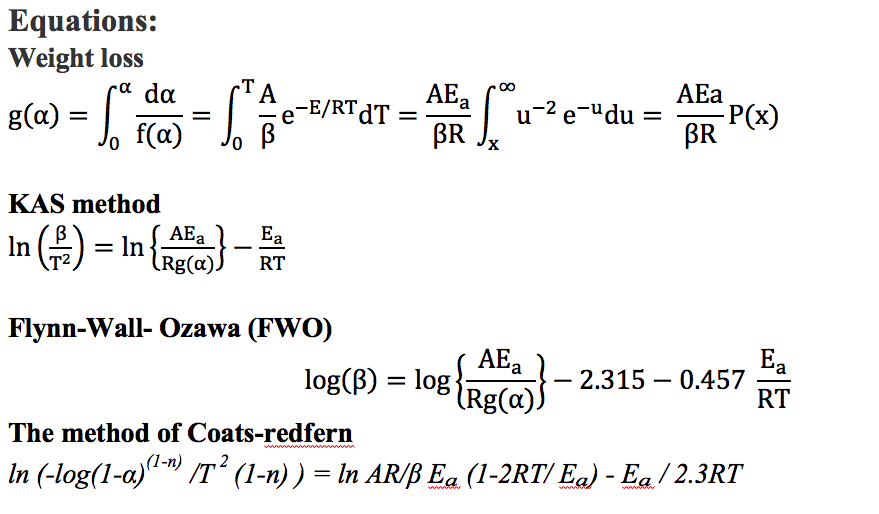

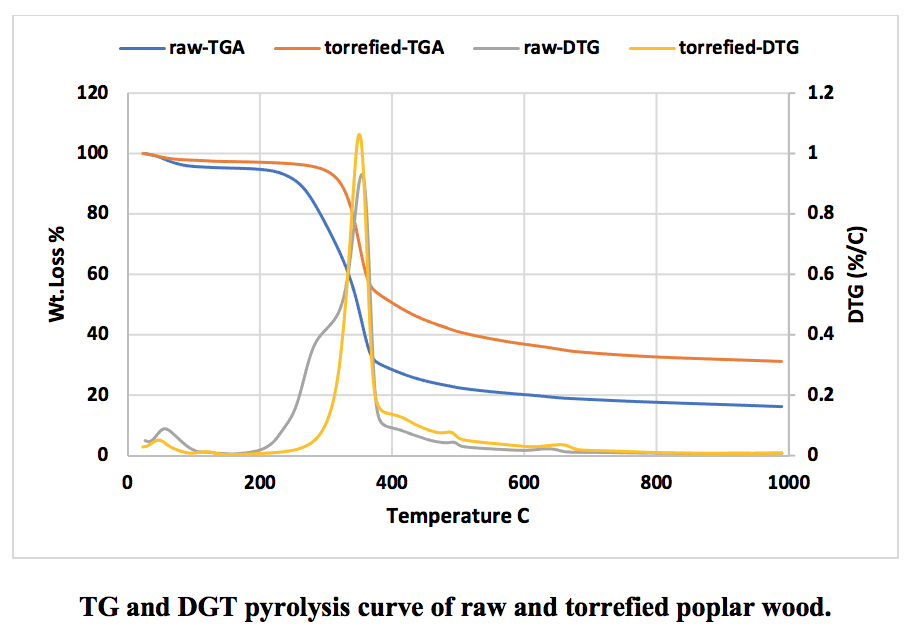

Physicochemical characteristics and pyrolysis kinetics of raw and torrefied hybrid poplar wood (NM6 – Populus nigra).

Reference: Bharat Regmi B., Animesh Dutta, Ranjan R. Pradhan & Precious Arku (2020) Physicochemical characteristics and pyrolysis kinetics of raw and torrefied hybrid poplar wood (NM6 – Populus nigra), Biofuels, 11:3, 329-338.

Link: https://doi.org/10.1080/17597269.2017.1368058

Summary: The research work is an attempt to focus on thermal kinetics of raw and torrefied hybrid poplar wood (Populus nigra – NM6). The results of the experiment under the optimal condition based on mass and energy yield, which was found to be 270 °C, were evaluated for physiochemical and kinetic characteristics. Comparative pyrolysis of raw and torrified hybrid poplar wood was carried out to understand the enhancement of biofuel characteristics and kinetics after torrefaction.

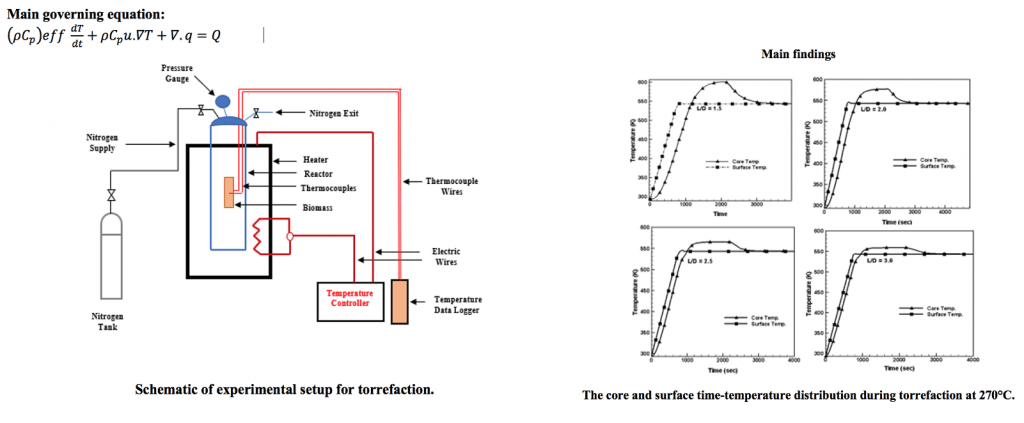

Modelling of heat transfer during torrefaction of large lignocellulosic biomass

Reference: Regmi, B., Arku, P., Tasnim, S.H. et al. Modelling of heat transfer during torrefaction of large lignocellulosic biomass. Heat Mass Transfer 54, 1989–1997 (2018).

Link: https://doi.org/10.1007/s00231-018-2300-z

Summary: Regarding the commercialization of torrefaction technology, this study has examined heat transfer inside large cylindrical biomass both numerically and experimentally during torrefaction. A numerical axis-symmetrical 2-D model for heat transfer during torrefaction at 270°C for 1 h was created in COMSOL Multiphysics 5.1 considering heat generation evaluated from the experiment. The model analyzed the temperature distribution within the core and on the surface of biomass during torrefaction for various sizes.